Research and Development

Research and Development Services for Materials and Procedures

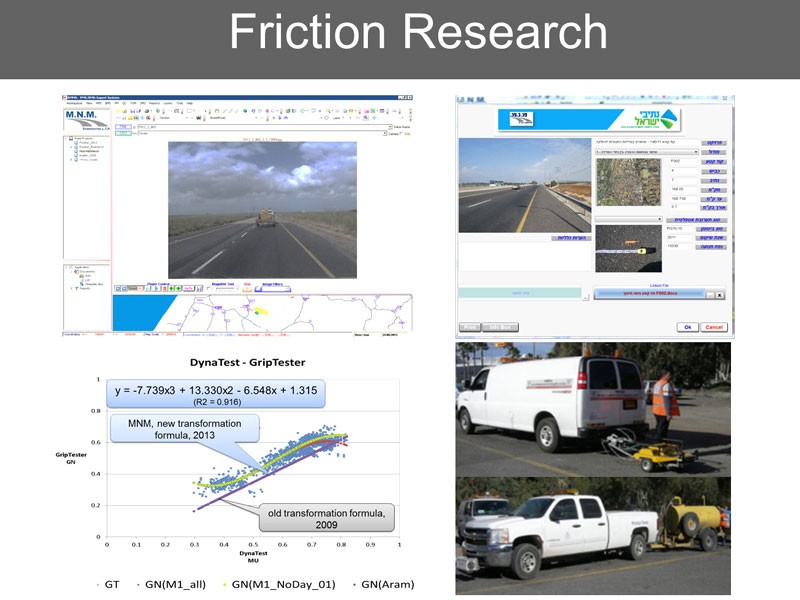

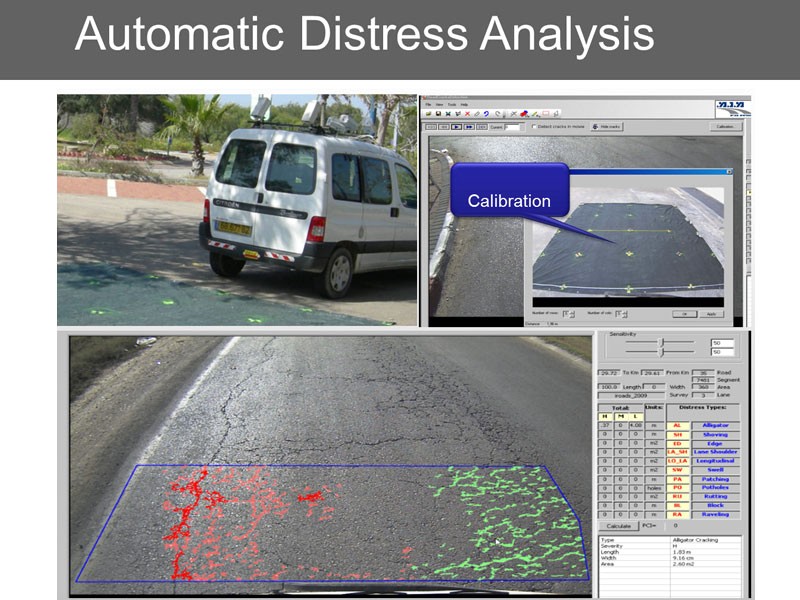

M.N.M. Engineering experts develop products and as well as provide research services to governmental and local agencies. Cutting-edge materials that we develop include advanced asphalt-concrete (AC) mixtures and porous (“silent”) asphalt. Advanced procedures that our professional team has researched and developed include innovative QA/QC processes that make use of FWD (Falling Weight Deflectometer), GPR (Ground Penetrating Radar), Intelligent Compaction in-situ, Accelerated Pavement Tester (APT), Automatic Distress Analysis and more.

Our R&D projects have assisted our customers in adopting cutting-edge technologies, implementing LTPP (Long-Term Pavement Performance) programs, and saving on pavement construction and maintenance costs.

Examples for Material and Process Research Projects Lead by Our Experts:

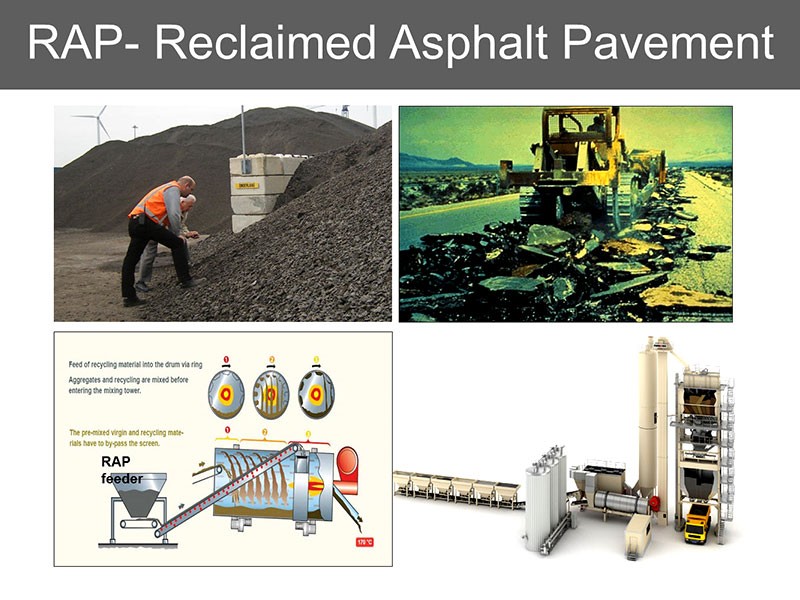

Recycling of HMA using Reclaimed Asphalt Pavement (RAP). Project was ordered by Israel’s Department of Transportation and the INRC (Israel National Roads Company).

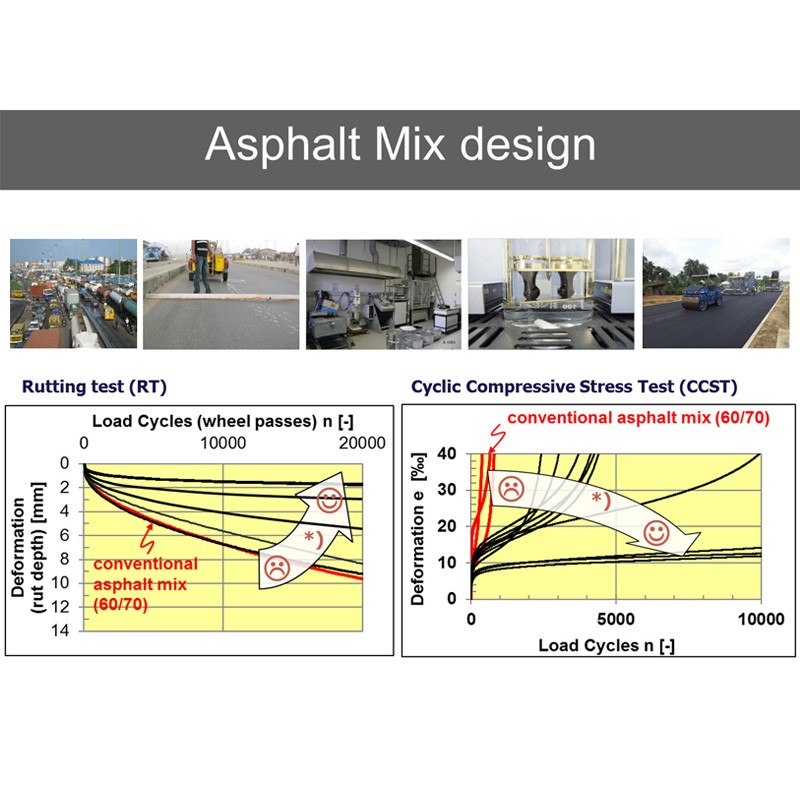

Development of new AC mixtures with high resistance to rut: The project included literature study, field research, lab testing, asphalt plant tours, bid papers, and defining specifications. The customers of this project were the Federal Republic of Nigeria’s DOT, the Israeli Air Force and the Israeli Department of Defense.

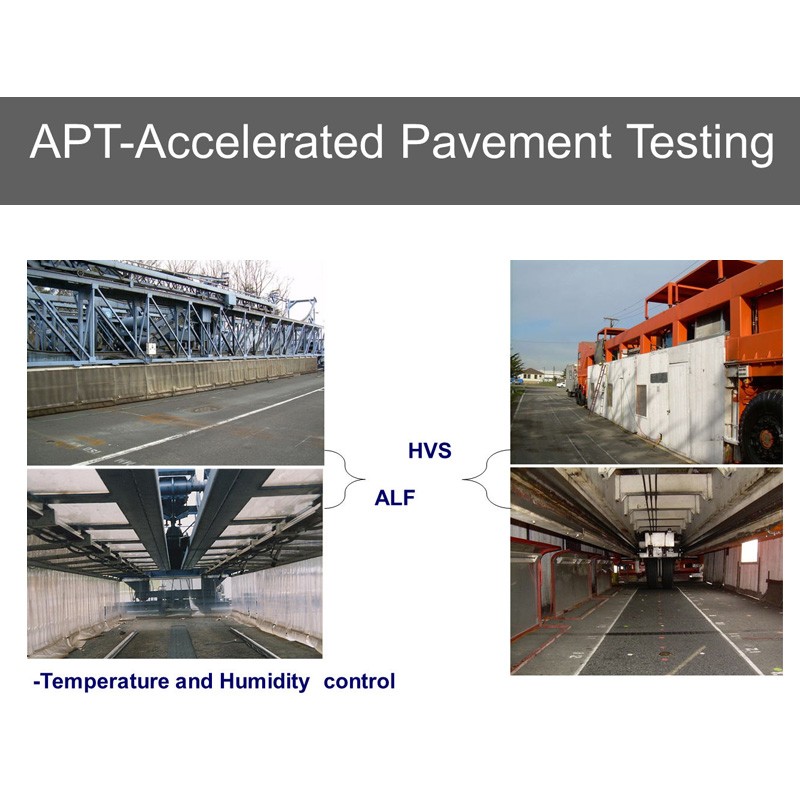

Accelerated Pavement Testing (APT): This project, ordered by Israel’s DOT and National Roads Company, included an engineering study, field research in APT facilities in Europe and North America, profitability analysis, bid papers, and recommendations for implementation procedures.

QA/QC procedures: Our experts have developed for Israel’s DOT and National Roads Company (INRC) innovative procedures that make use of an FWD (Falling Weight Deflectometer) during the construction of roads. These advanced techniques allow recognizing, during road construction, weak areas that are likely to cause future road failures, and enable tracking and achieving uniformity in the engineering properties of the compacted fill layers. These capabilities effect the life cycle and reduce maintenance costs during the design period. The project included research and determination of threshold values, analysis software, bid papers and defining special-purpose specifications.

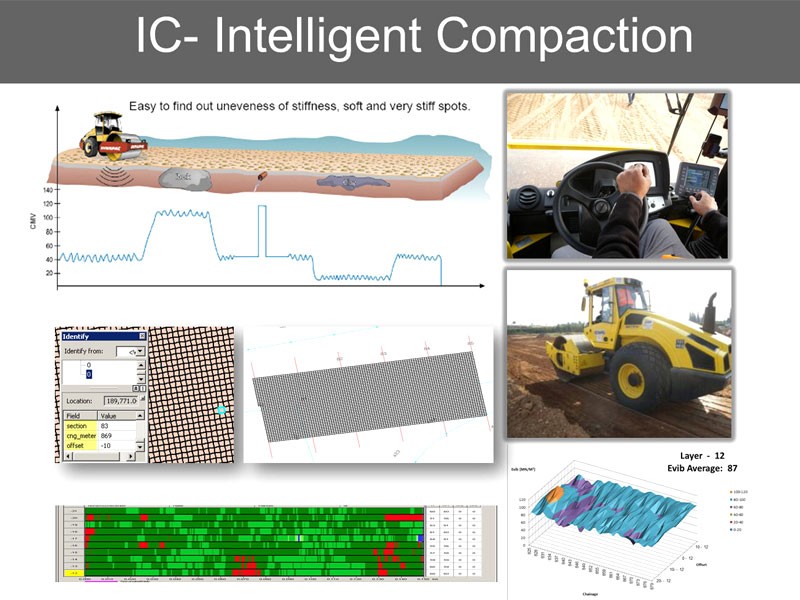

Intelligent Compaction in-situ: In order to support the adaption of IC systems in the market, our experts have conducted an engineering study as well as field research, which inspected the system operation and data collection process. The field research also focused on the implementation process and the necessary conditions for successful integration of Intelligent Compaction systems with existing construction, quality methods and standards.

Examples for Special-Purpose Software Development Projects:

Our engineering and software specialists have developed a threshold-based FWD analysis module for quality control. This software includes homogenous section analysis (according to Appendix J of the AASHTO (1993) Guide for Design of Pavement Structures) - see image above.

For pavement structure studies, we have developed a video recognition software module for automated pavement condition & distress analysis. This system can automatically detect pavement defects in video data captured by road survey devices.